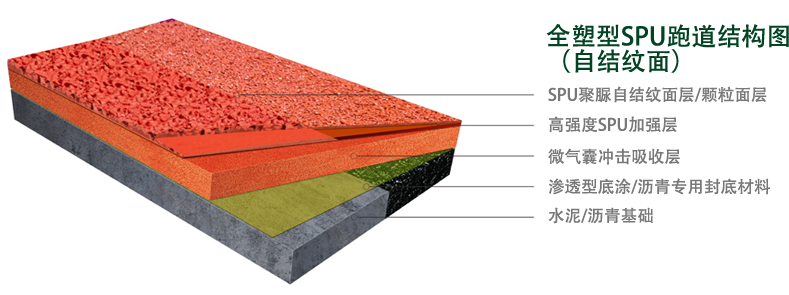

全塑型SPU跑道 | 自结纹面

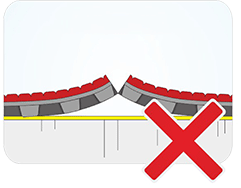

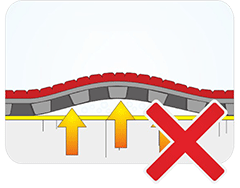

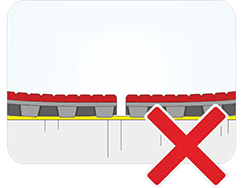

全塑型SPU跑道采用一体无缝成型工艺,并且能达到二次平整的作用;全封闭无缝结构有效隔绝外来雨水对赛道的破坏,让赛道更持久耐候、翻新容易;全面解决建材产品因收缩使接缝开裂,雨水浸泡渗入破坏赛道,造成弯道变形、接缝起拱、渗水鼓泡等质量问题。

全塑型SPU跑道应用范围

校园

田径运动场、体育馆跑道

步径

小区、公园、游乐园

康体场所

健身房、舞蹈室

专业赛事

运动场、训练场

全塑型SPU跑道性能优势

国际级标准环保

无毒无味,通过中国环境标志,从原材料到成品全面达标新国标和上海标2.0

氯化石蜡

不含氯化石蜡

MOCA

不含MOCA

苯

不含苯类溶剂

TDI

不含TDI

VOC

室内级VOC限量

重金属

不外加重金属

竞赛级专业品质

国际级赛场主流的上硬下弹结构,为运动提供合理的保护和专业的竞技辅助

持久稳定的冲击吸收性能

微气囊结构为运动带来的优异缓冲保护

保证运动竞技的垂直变形量

高强度聚脲材质保障的专业运动竞技状态

创新科技成果

全塑型SPU自结纹跑道融合了可控闭孔微发泡技术,和改性聚脲自结纹面层技术,是高新技术产品

1 受力后压缩缓冲

2 起步回弹助力

3 卸力瞬间恢复

持久耐用性加倍

全塑型自结纹SPU跑道,拥有更耐磨的聚脲自结纹面层,纹理胶浆固化成型,无脱粒烦恼;高倍抗紫外线性能,更耐候耐老化,色泽持久鲜艳。面层一体无缝成型,底涂高渗透性,出色耐水防潮。

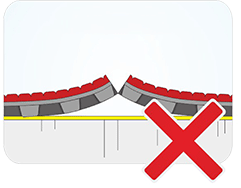

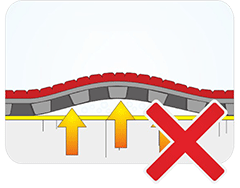

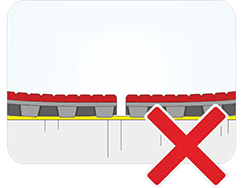

弯道变形

拼缝起拱

渗水鼓泡

拼缝开裂

全塑型SPU跑道常规色

红色

黄色

绿色

蓝色

硅PU施工步骤

1、基础处理

根据施工指引处理水泥或沥青基础,处理完毕后,基础强度达到建筑混凝土标准C25强度。

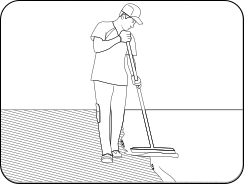

2、滚涂底涂

将专用底涂分一道滚涂或刮凃于基面。

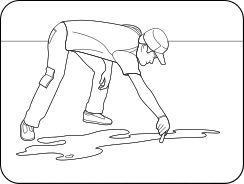

3、积水修补

整个场地洒水,找出积水的地方,用笔圈出,晾干场地;用直尺或刮板涂刮找平积水处。

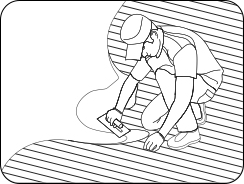

4、封底找平

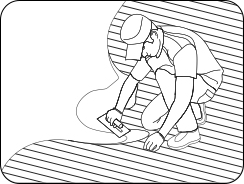

用镘刀找平材料刮涂到基础上。

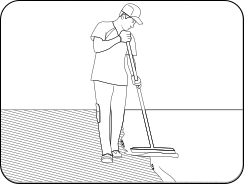

5、刮涂弹性层

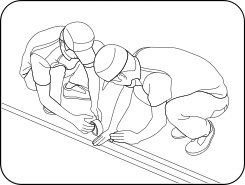

用齿刮进行刮涂,根据厚度标准进行用量分配刮涂

6、刮涂加强层

用齿刮进行刮涂,根据厚度标准进行用量分配刮涂

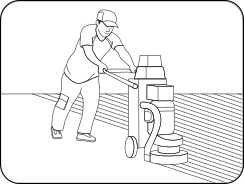

7、打磨加强层

加强层固化后,用专用砂带机带80目的砂纸进行整体打磨处理。

8、刮涂面层

根据不同的场地用途调制材料,并使用齿刮将材料刮涂在基面上。

9、划线

按标准尺寸量度定位,标出界线位置,用专用划线漆涂刷于美纹纸间。

微信公众号

公司

产品

案例

微信公众号

Copyright©2023 浙江绿能体育产业股份有限公司/隐私政策/ 浙ICP备2021030606号-1